News

Needleless Corporation announced that it has successfully passed the latest audit and certification of the Quality Management System for Medical Devices (QMS)

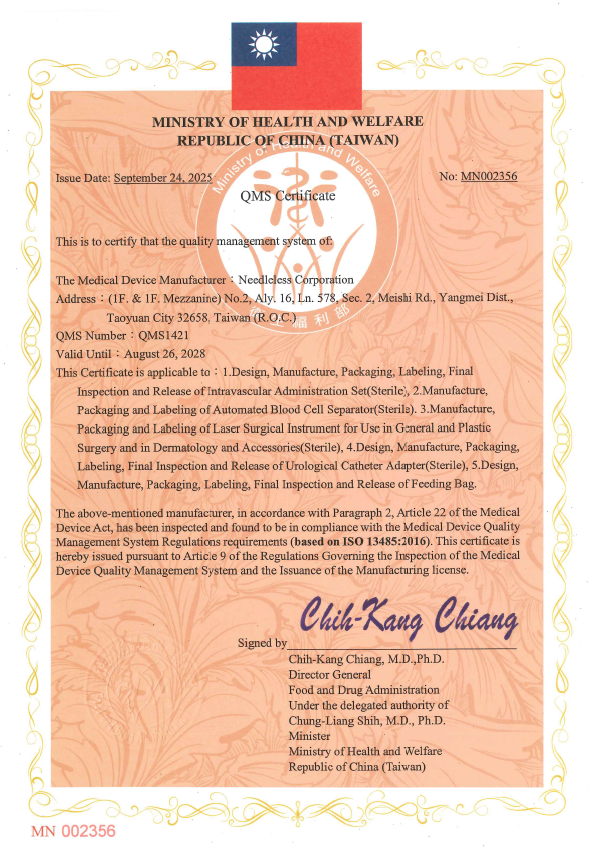

Needleless Corporation announced that it has successfully passed the latest audit and certification of the Quality Management System for Medical Devices (QMS) conducted by the Taiwan Food and Drug Administration (TFDA) under the Ministry of Health and Welfare.

The new QMS Certificate, numbered QMS1421, is valid until August 26, 2028. This renewal not only maintains the company’s existing manufacturing quality assurance system but also signifies a major expansion in its scope of design and manufacturing, underscoring Needleless Corporation’s continuous commitment to technical excellence and regulatory compliance at the international level.

Expanded Certification Scope Demonstrates Diversified Manufacturing Capabilities

The expanded scope of the new QMS Certificate covers the following product categories:

-

Intravascular Administration Set (Sterile): Design, Manufacture, Packaging, Labeling, and Final Release

-

Automated Blood Cell Separator (Sterile): Manufacture, Packaging, and Labeling

-

Laser Surgical Instrument for General, Plastic Surgery, and Dermatology (Sterile): Manufacture, Packaging, and Labeling

-

Urological Catheter Adapter (Sterile): Design, Manufacture, Packaging, Labeling, and Final Release

-

Feeding Bag: Design, Manufacture, Packaging, Labeling, and Final Release

The expanded certification scope demonstrates that Needleless Corporation not only possesses stable manufacturing capabilities in medical disposables but has also successfully advanced into clinical and surgical device applications.

This achievement highlights the company’s R&D and quality teams’ ability to manage a multi-product portfolio under an integrated and compliant quality management framework.

Achieved Through Rigorous Audits, Demonstrating an Excellent Quality System

The QMS Certificate was issued by the Taiwan Food and Drug Administration (TFDA) under the Ministry of Health and Welfare, in accordance with the Medical Device Act and the Regulations on Medical Device Quality Management Systems, based on ISO 13485:2016.

The certification process required a comprehensive on-site audit and document review, covering design control, process validation, risk management, final release, traceability, and nonconformity handling—making it one of the most rigorous and challenging quality system assessments in the medical device industry.

Passing all audit items in a single review demonstrates that Needleless Corporation’s internal QMS operates with exceptional rigor and continues to comply with international standards for medical device manufacturing.

Driven by International Standards, Advancing Steadily Toward the Global Market

The expanded QMS certification scope marks Needleless Corporation’s official qualification to design and manufacture multiple categories of medical devices, establishing a strong quality foundation for future global expansion into markets such as ASEAN, Europe, and the Middle East.

The company will continue to enhance its quality management system in accordance with ISO 13485:2016 and TFDA medical device regulations, driving continuous improvement and risk-based management to ensure that every product released meets the highest standards of safety and performance.